Tighter budgets strengthen need for efficient tool management

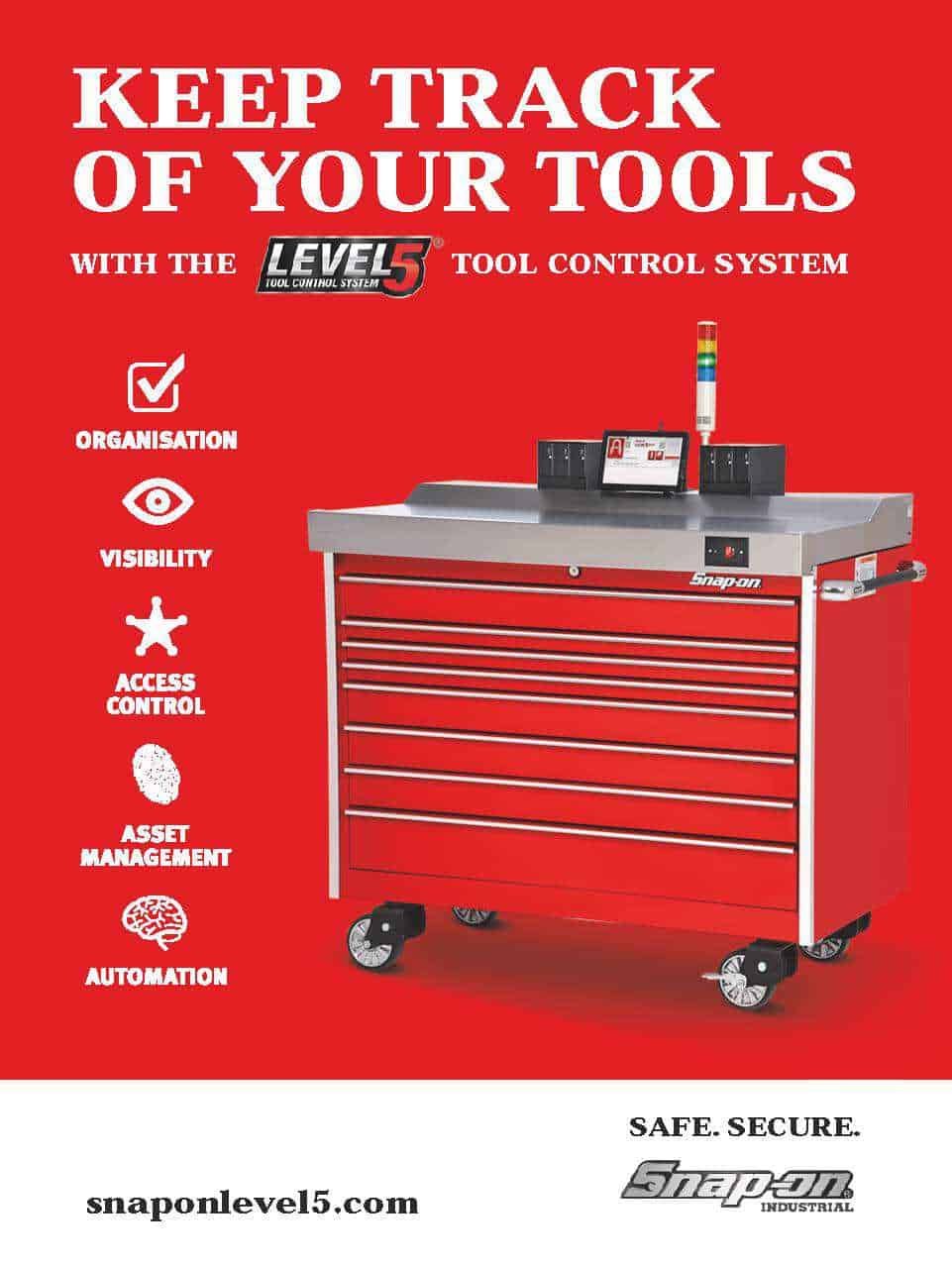

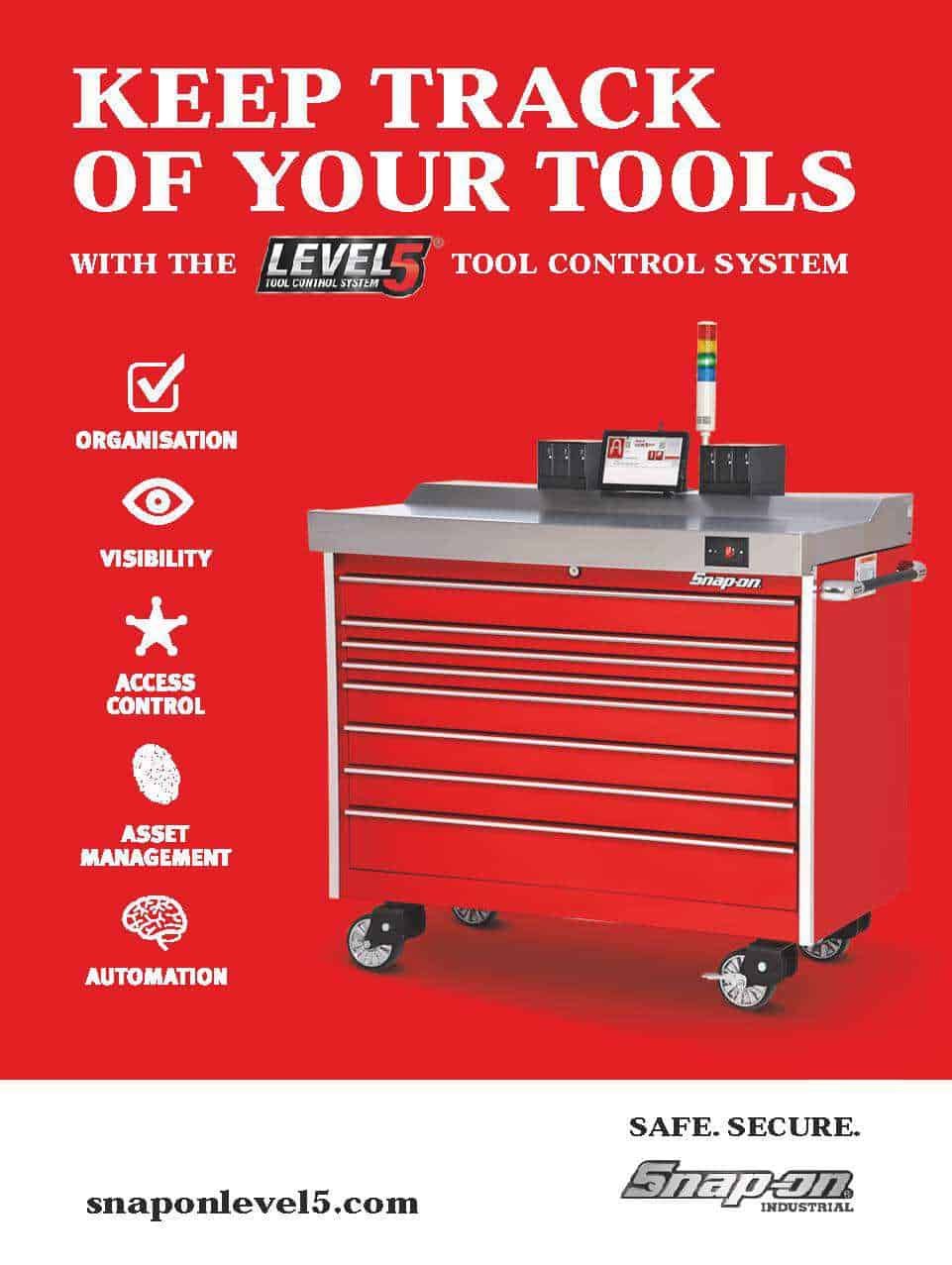

As engineering managers cope with relentless pressure to deliver improved productivity, often with fewer skilled hands and tighter budgets, the benefits of Snap-on Level 5 tool storage and management become stronger than ever.

As engineering managers cope with relentless pressure to deliver improved productivity, often with fewer skilled hands and tighter budgets, the benefits of Snap-on Level 5 tool storage and management become stronger than ever.

Snap-on Level 5™ automated total asset management system brings order to any workplace, enabling engineers and technician to track tools from one central point. It provides complete reports on everything managers or supervisors need to keep an eye on, even advising when a tool needs to be refilled or re-ordered.

The threat of foreign object damage is a real and present danger but Snap-on Level 5 minimises the risk of human error, ensuring greater protection against FOD.

Engineered to track individual tools by user, without bar codes, scanners, RFID tags or other add-ons, the system works at the speed its users demand. Other systems require additional steps to scan or log activity but the Snap-on system does this automatically.

Level 5™ ATC boxes are network ready, using either Ethernet or wireless connection.

That enables users to review activity at all Level 5 boxes in your location from one central computer, avoiding the time consuming need to inspect each box.

Major benefits include:

- No individual tool scanning required

- No RFID tags to install or replace

- No limitations on tool size: from ¼” screwdriver bit to just less than the size of the drawer

- Intuitive interface, with an easy to use a touchscreen

- Audible voice confirmation of tool removal and replacement

- Automatic locking for maximum security

- Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed

The administrator can identify active users, view all boxes on the network, whether they are on or off-line, and see the status of each box including the number of tools issued. System alerts, for example sending e-mails to supervisors, can be customized for lost or broken tools or to meet calibration requirements. Reports can be created on each tool’s frequency of use, inspection and calibration dates as well as specific location requirements.

Finding the right tool for the job in hand can take up even more time if the tool is difficult to spot. Snap-on solutions for better visibility include coloured, oil resistant foam inserts in profiled drawers, along with easily identified tool handles.

The more organised the workplace the easier and quicker it is to meet schedules. Snap-on offers complete tool audits to determine what level of tool control each customer needs. Special tool sets can be designed to meet specific requirements.

Cabinet security is essential to efficient tool management. Snap-on’s solution to the problem of using keys, which can be lost of shared with others, is simple: don’t use keys at all.

Snap-on Level 5 boxes are equipped with Keyless Access Control, giving users the ease of access they need with security built in. The control system can be configured with magnetic cards, barcodes, PIN numbers and proximity cards. Snap-on’s proprietary software enables managers to control access from a system or network.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snap-on’s automated system takes tool management to an entirely new level, giving workshop managers and other authorised users easy access to the tools they need for the job in hand while protecting against foreign object damage. The ability to monitor several boxes from one central computer offers managers a huge time saving advantage.”

This article originally appeared in EMS Magazine Aug/Sept 2021

Snap-on's Level 5 asset management system is network ready

Snap-on’s Level 5™ asset management system is network ready

As engineering managers cope with relentless pressure to deliver improved productivity, often with fewer skilled hands and tighter budgets, the benefits of professional tool storage and management become stronger than ever.

Snap-on Industrial’s Level 5™ automated total asset management system brings order to any workplace, enabling engineers and technicians to know exactly where to find every tool they need, when they need it, saving time and easing stress.

How useful would it be if all your workshop’s valuable tools could be tracked from one central point? Snap-on’s Level 5™ system makes that possible. It provides complete reports on everything managers or supervisors need to keep an eye on. They are even informed when a tool needs to be refilled or ordered.

And then there’s FOD. The threat of foreign object damage is a real and present danger in many engineering workplaces. Using Snap-on Level 5™ minimises the risk of human error, as automated tool control constantly tracks every tool and detects which tools have been removed or returned, ensuring greater protection against FOD.

Engineered to track individual tools by user, without bar codes, scanners, RFID tags or other add-ons, the system works at the speed its users demand. Other systems require additional steps to scan or log activity. The Snap-on system does this automatically so users save time and don’t have to depend on other steps to ensure accurate results.

Snap-on’s Level 5™ ATC boxes are network ready, using either Ethernet or wireless connection. That enables users to review activity at all Level 5 boxes in their location from one central computer, avoiding the time consuming need to inspect each box.

Major benefits of the system include:

- No individual tool scanning required;

- No RFID tags to install or replace;

- No limitations on tool size: from ¼” screwdriver bit to just less than the size of the drawer;

- Intuitive interface, with an easy to use touchscreen

- Audible voice confirmation of tool removal and replacement

- Automatic locking for maximum security

- Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snap-on’s automated system takes asset management to an entirely new level. The ability to monitor several boxes from one central computer offers a huge advantage to engineering managers.”

For technical details visit: www.snaponlevel5.com, call (01536) 413904 or

e-mail: [email protected]

Snap-on Tethered Tools Protect Lives When Working at Height

Snap-on Tethered Tools Protect Lives When Working at Height.

Oil and gas engineers and technicians required to work at height, often in challenging offshore locations and appalling weather, are well aware of the risk of hand tools or equipment falling or being dropped – and of the potential consequences.

As well as posing a major threat to anyone working below, falling tools can also cause serious damage to vital systems and machinery, causing highly expensive downtime.

Dropped objects are consistently the third most frequent cause of death or serious

injury in the oil and gas industry. A hand tool such as a torque wrench falling

from height will accelerate to around 80mph before it hits the ground, with a force of impact

similar to that of a plunging domestic washing machine.

The success of the safety focused Tools@Height programme from Snap-on Industrial depends

upon the Tethered Tools Protect tethering all tools to prevent them inadvertently falling or being dropped. All

tools are designed with strong, integrated fixing points to enhance safety and functionality when used at height or near critical assemblies.

Says Richard Packham, Snap-on Industrial’s Director, UK & Europe: “No responsible

engineer or technician wants to work at height, with all its challenges, without knowing they can rely totally on their safety equipment to protect both themselves and others working below

them, as well as safeguarding vital systems and machinery from damage.”

Working at heights has always been in our DNA.

Snap-on Industrial's special program for professionals working at heights.

“At Snap-on we follow an extensive research, development and quality management programme which has resulted in advanced design, manufacturing, testing and operating procedures covering safety and dropped object prevention.”

“Our objective is to continue being a totally professional, dependable company which contributes to its customers’ wellbeing by offering the highest standard of safety and productivity solutions.”

The oil and gas industry has taken a global lead in working to combat the threat caused by falling tools and other objects. Tethering tools to their users is one of the many vital precautions which companies require of those working on platforms or onshore.

Years ago Snap-on pioneered anti-drop solutions to benefit construction workers building skyscrapers in the USA. Its Tools@Height range has been developed in consultation with the most demanding users to understand exactly what functionality is required.

The result is a wide range of tools which incorporate fixings to enable hand and power tools to be securely tethered to Snap-on lanyards, bags, pouches and belts. This is not only ideal for using tools but also provides secure tool transportation to the workplace.

Four holes are better and safer than one. Snap-on Tools@Height sockets, adapters and extensions have a locking hole on all four sides. Drive tools and ratchets have a locking pin which fits into the side locking hole to ensure positive locking. Less secure attachments with a hole only on one side are at risk of falling apart.

The Snap-on Tools@Height range reduces the risk of damage to equipment engineers are working on and, more importantly, to the people they are working with.

There is compelling evidence that using tools designed and manufactured to be tethered is a lot safer than adapting existing tools for working at height. Engineered attachment points do not interfere with the functionality or efficiency of tools designed to be tethered.

When working at height engineers or technicians should retain three points of contact for their safety: two feet on a platform and one hand on a secured infrastructure. To address the risk caused when it’s necessary to use both hands to attach a tool to a tethering device Snap-on have developed safety solutions.

For example, a tool belt in which each tool as its own pouch or holster with a tethering device already installed. This enables tools to be accessed and replaced with just one hand.

Turnkey solutions: Snop-on Tethered Tools Protect supplies individual tools or customer specific kits. Components are delivered to customers’ premises fully assembled and ready for immediate use.

Snap-on Account Managers have the knowledge and experience to train customers’ teams in the safe and efficient use of Tools@Height products. Standardised positioning of the fastening elements reduces time spent in training. Tools@ Height can be implemented for a fraction of the cost of in-house systems.

Fixings: include safety chucks, Kevlar strings or Dyneema strings for screwdrivers, spring connections for wrenches, loops, eye bolts, shackles and safety pins for pliers, hammers and other tools.

Lanyards: retractable Snap-on lanyards are certified against international standards. They are quality tested in both static and dynamic tests in conditions more rigorous and demanding than any likely to be encountered. For the dynamic test a security coefficient 2, factor 2 test is performed.

Their lanyards, capable of holding up to 12kg, feature universal attachments for tools which do not have any integrated attachment point. Several types of lanyard are available, including carabiner, fixed loop, exchangeable loop, retractable and wrist lanyards.

The carabiner lanyard, manufactured in high tenacity polyester, fully extends to 120cm and can hold up to 3kg maximum tool weight (3 daN).

Its carabiners are non-removable and high strength webbing and self-retracting inner coil jointly absorb shock.

Snap-on’s wrist lanyard extends to 60cm, holds up to 1kg weight and features an exchangeable loop with barrel lock.

Additional quick release connections are available but, for safety reasons, their locking system is compatible only with the specific lanyard they are intended to be used with.

Pouches and belts: designed to make life easier, as well as safer, Snap-on tool pouches and belts are made from hardwearing 600x600d polyester to resist heavy duty wear and tear.

They provide flexible solutions with rings to attach lanyards and hooks to hold tools in loose connectors. Multiple inner compartments offer tool organisation, while quick-access external pockets include one to hold a socket set and another for a water bottle. Adjustable chest and shoulder safety straps provide maximum comfort.

Belts are available in different versions, providing up to four hooks for loose connectors, each capable of holding up to 3kg per hook, plus up to three rings for lanyards, with a capacity of 100 daN per ring.

Separate power drill and hammer holders are also available.

Tool Control Pushes Food Safety to New Levels for KP Snacks

Tool Control Pushes Food Safety to New Levels for KP Snacks.

KP Snacks, which is part of the Intersnack Group, has been manufacturing quality snacks across the UK since 1953.

The company employs around 1,800 people across its 5 manufacturing sites & headquarters, producing savoury snacks, including brands such as McCoys, Hula Hoops, KP Nuts Pom-Bear and Phileas Fogg, as well as retailer brand products.

Food safety is a critical component of any food manufacturing process, typically covering everything from handling and preparation to storage. But with new legislation and tighter controls on health and safety, KP Snacks has announced that it is taking food safety to another level, with the introduction of tool management onto the production line.

Whilst KP Snacks had multiple tools on the factory floor, there was no system in place to track specific tools or carry out audits.

Jeremy Derbyshire, Site Director at KP Snacks explains: “For KP Snacks, tool control was very much an embedded standard in industries such as aviation but very few suppliers had made the crossover into the food industry. The food safety of our products is of paramount importance to KP Snacks and we take every step possible to safeguard our consumers, constantly challenging ourselves to improve and exceed our customer requirements.

“Researching the market, the same name kept coming up as market leaders in tool control: Snap-on Industrial. The company has a solid track record in dairies and an understanding of the challenges that food manufacturers face when it comes to tool control.”

KP Snacks started working with tooling solutions specialist Snap-on Industrial in 2013, initially gaining an understanding of the way it could control and manage its tool system within its manufacturing sites.

KP Snacks signed up to Snap-on’s Level 5 NTC (Networkable Tool Control) system. This offers staff the opportunity to manage a virtually unlimited number of lockable tool storage units simultaneously for complete system control. It also allows tools and assets to be controlled in real-time, reducing the risk of foreign objects in food.

The keyless entry allows authorised staff at KP Snacks access to the tools they need, while the operating software within the NTC system tracks access based on employee ID key cards. All tools are serialised and linked to a specific toolbox via laser etching. The NTC system enables the user to report tool events such as being lost, broken or away to calibration (and other locations) directly at the toolbox. This information, plus toolbox access records, is stored within log files on the toolbox and can be viewed or printed at any time. This provides a full audit record of toolbox access (or declined access) by user, time and date and a complete history of tools with events marked against them such as being lost or broken.

Snap-on’s solutions gave KP Snacks the level of customisation they required.

Gareth Dughan, Engineering Manager at KP Snacks and responsible for the tooling project, explains why an easy to use, real-time tooling system was so important: “Each area of our factory requires different tools so we found that we needed to tailor the tool inventory to each specific area. The level of customisation Snap-on provided allowed us to make this project more cost effective by ensuring that we only purchased the tools needed for a certain area, thus avoiding unnecessary and costly duplication. We were also impressed by the laser etching service that ensured that each individual tool could be identified to further improve our traceability.”

This has produced important time savings for the staff on the production line, explains Gareth: “Producing an inventory of tools every day wasted precious time with over 100 members of staff spending up to 15 minutes a day managing their tools across three shifts. Using Snap-on meant we were able to manage our time better and the NTC system has helped make the process seamless.

Jeremy concluded, “The tool chests have enabled us to easily demonstrate that, when it comes to the safety of our products, we are willing to invest in the very best solutions available. Food safety and compliance has continued to improve across our factories and our factory floors have benefited from having all the tools in easily accessible storage units.”

Company Profile

Since 1920 Snap-on Industrial has been a world leading tooling solutions specialist with unrivalled expertise in providing bespoke solutions across a diverse range of industry sectors, which include natural resources, defence, aviation, construction, as well as manufacturing, rail and food production.

Snap-on Industrial provides companies with strategic advantages in addressing the challenge of increasing profitability, through reduced downtime, increased productivity and cost control.

Eurostar adopts Automatic Tool Control system from Snap-on Industrial

Eurostar adopts Automatic Tool Control system from Snap-on Industrial.

It all began in 2013 when Eurostar acquired some ControlTech industrial electronic torque wrenches from Snap-on and were looking at options to control them at point of use along with other high value, specialist & calibrated tooling.

After careful consideration of various different options Eurostar decided that the Snap-on Automatic Tool Control boxes would best suit their needs, primarily because it was the most user friendly and least intrusive system for their end users.

Once installed at point of use the Automatic Tool Control boxes only require the user to touch their company ID pass against the card reader and the tool box automatically accesses the users account & unlocks the box. The convenience of use is the main reason why the Snap-on ATC tool boxes have been so well received by the end users at Eurostar.

Using advanced digital imaging technology and proprietary software every drawer open, close & tool transaction is recorded at the speed of use and stored both locally on the box and in a central database that can be accessed remotely using the intuitive ATC admin client software. As soon as the user has the tools they need, the Automatic Tool Control is locked and secured with a single press of the touchscreen and they can then continue with their work.

The convenience of use is the main reason why the Snap-on ATC tool boxes have been so well received by the end users at Eurostar.

The first ATC was installed in the bogie drop facility during 2014 as a trial and proof of concept, the location was selected as it is the harshest environment on site, the work is heavy, dirty and temperatures can vary widely whilst the shed doors remain open for the duration of the work.

Following this successful trial 3 more ATC’s were installed at ground level between roads 4 and 5 in the main maintenance shed to cater for the 374 fleet introduction in 2015.

A further 4 ATCs were installed on the high level gantries on roads 3 & 4 in 2016 to provide tooling for roof mounted equipment work also on the new 374 fleet. Then one more ATC was installed at ground level outside the team leaders office in the main shed containing keys and uncommon tooling not found elsewhere, bringing the total number of Automatic Tool Control boxes in service at the depot to 9 by the end of 2016.

ATC Positioned at Point of Use in the Centre of the Main Shed

Fast forward to today building on the success of the Automatic Tool Control programme, expansion of the 374 fleet and further modification of the depot to maintain them, Eurostar have now increased the number of ATC boxes in service at Temple Mills to a current total of 23, making them one of the largest adopters of the Snap-on Automated Tool Control system in the UK, and they are currently distributed as follows:

- Bogie Drop x 1

- Main Shed Ground Level x 10

- Main Shed High Level Gantries x 12

Based at the depot there are around 20 teams of engineers, all of these have a basic personal issue tool kit, and most of them also had two team tool cages each in the 450 Meter long shed. One of the objectives of the Automatic Tool Control project was to provide tool availability at point of use that would then allow Eurostar to reduce the need for these team cages by 50%, by removing any calibrated and specialist tooling from these cages and placing them into the ATCs so that they are accessible to everyone 24/7.

Half of the engineering teams work a 7 days on 7 days off shift pattern, so the tools contained within their team cages were locked away for 6 months of the year. This was obviously not a great use of the company’s expenditure on tooling, and with regard to hand tools these teams had all amassed a varied selection over the last 25 years, so no two teams had the same tool inventory and until recently no one person knew the contents of all of these team tool cages.

ATC Located Outside Team Leader Offices Containing Keys and Non Standard Tooling

Today Eurostar have around 300 registered ATC users and as the ATC coverage within the main shed has grown, more and more tools have been placed under ATC control so the engineering teams have come to rely far less on their personal and team tools, instead going to the nearest ATC to obtain what they need from there.

They have also found the ATCs a great help when carrying out repairs or unplanned interventions, when they are far from their team cages or the Stores, as they can easily grab a pressure druck or fluke from the nearest ATC, instead of walking all the way back to the stores or their team cage. This is another reason why ATC was so well received by the shop floor engineers, it’s convenient and makes their life easier plus the business has benefited from far less unproductive time

Half the engineering teams work a 7 days on 7 days off shift pattern, so the tools contained within their team cages were locked away for 6 months of the year.

The ATC admin software tracks everything that happens both at the ATC and via the software then stores it in an easily searchable way, thus making it very useful for record keeping and audit purposes. The software also allows some feedback by the ATC to the end users and vice versa, so if a tool is removed by an ATC administrator for calibration or repair, a status can be set against that tool either via the ATC touchscreen or the admin software. Conversely if a user wishes to report a broken tool and request replacement or repair, they can do this via the touchscreen on the box which will then send an alert to the ATC administrator.

Scott Seacombe, Industrial Engineer and ATC Project Manager said: “The ATC software is an absolute gem, it’s amazing how useful keeping accurate transaction history for tools can be, and the images generated from each drawer open and drawer close can be extremely helpful.”

Through 2019 Eurostar have further plans to add at least one more Automatic Tool Control and are also considering Snap-on’s TC Max asset management software to control all remaining tooling still held in the stores, this software will also be capable of managing consumables and free issue items. Perhaps the biggest advantage of TC Max is that it will work seamlessly with the existing ATC admin software ultimately providing a single searchable database of every tool the company owns together with its current location and usage data.

Company Profile

Since 1920 Snap-on Industrial has been a world leading tooling solutions specialist with unrivalled expertise in providing bespoke solutions across a diverse range of industry sectors, which include natural resources, defence, aviation, construction, as well as manufacturing, rail and food production.

Snap-on Industrial provides companies with strategic advantages in addressing the challenge of increasing profitability, through reduced downtime, increased productivity and cost control.