Snap-on Tools

WHAT THE WORLD’S MOST DEPENDABLE TECHNICIANS DEPEND ON.

Critical industries rely on the techs – and the tools – that get the job done. And that’s why the world’s best techs trust Snap-on tools.

With a legacy of excellence, a commitment to a job well done and an unwavering work ethic, Snap-on tools live up to the highest standards: yours. For the critical, Snap-on is indispensable.

Salute to the Makers & Fixers

Keeping the world moving isn’t just your job. It’s your purpose.

Snap-on Toolshistory timeline

Five unique handles and ten sockets that snapped on interchangeably coined "Five do the work of Fifty", and launched Snap-on, a company that would shape the industry.

In 1920, a cultural shift was underway in the United States as the automobile was rising in popularity, creating the need for an emerging automotive repair industry. Joseph Johnson, an engineer from Milwaukee, had an idea that would revolutionise repair and make work easier for professional mechanics.

1930s

Dream Orders & Needs List

In the grip of the Great Depression, Snap-on salesmen would say to their customers, “Everybody is in a fix today – no money – but when you have money again, what tools will you need?” They called these “Dream Orders.” The novel idea quickly developed into a “Needs List,” and is still used with success today.

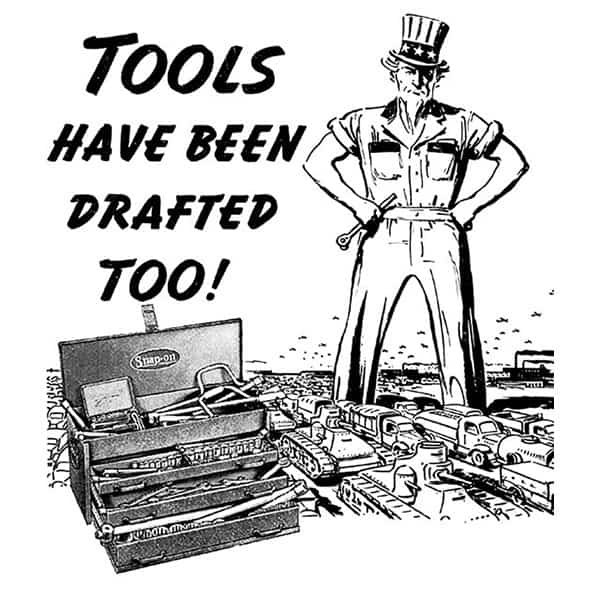

1940s

Essential to the War Effort

The early 1940s were marked by World War II and the military experienced severe tool shortages as a result. As a preferred supplier to the government, Snap-on was called into action, producing tools that kept air and ground equipment operating. Wartime demands also led to product innovations.

1950s

Booming Auto Industry

Post-war America began an era of optimism and growth of the middle class. The baby boom created a surge in home construction and a departure from the city to the suburbs.

Snap-on was well positioned to take advantage of this cultural shift; the dealer network continued to expand as a result of the fast developing auto repair industry and industrial sales accelerated as factories returned back to pre-war production.

1960s

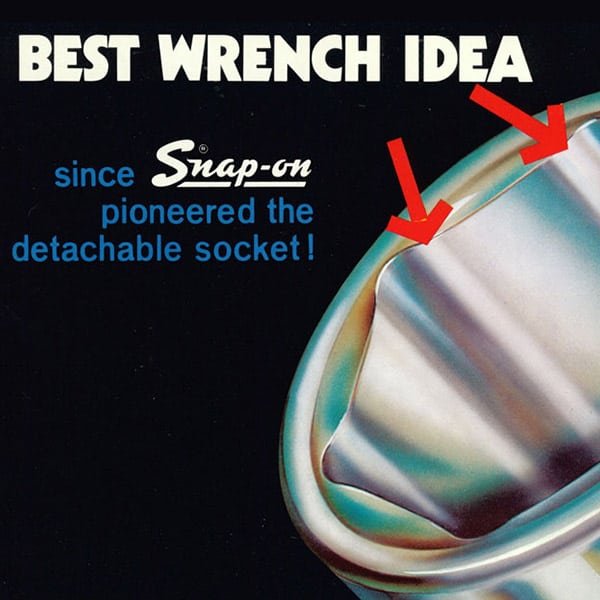

Creation of The Flank Drive

At this time, the aviation industry was making advancements in reducing space and weight by modifying fasteners, but was struggling with rounding of the fastener corners upon removal. The Navy sought Snap-on to solve this dilemma.

The solution, called the Flank Drive® Wrenching System, was issued two patents in 1965 and proved so popular that it spread throughout the Snap-on product line.

1980s

Soaring to New Heights

In the late 1980s, the “Soaring to New Heights in Customer Service” theme was created as the Corporation strived to reach the $1 billion sales milestone.

The eagle, a powerful, regal bird known for fast and furious flight, was chosen as the symbol to guide the Company to even higher levels of quality and customer service. In 1987, the $1 billion sales goal was achieved.

1990s

Continuously Evolving

Throughout the 1990s, Snap-on continued to expand product lines globally to better serve professionals in critical industries. More than two dozen companies were acquired.

With Sioux® and Williams® we extended our offering in power and hand tools for critical industries. In 1995 Snap-on purchased Eurotools, reaching professional tradesmen globally. In 1999, Snap-on acquired the Bahco® iconic brand.

2000s

Rapid Continuous Improvement (RCI)

RCI is a structured set of tools and processes, used by associates globally to eliminate wasted effort and create productivity and quality, leading to sustainable operating efficiencies.

Beginning in 2005, Snap-on enlisted the masters of the Toyota Production System, Shingijutsu, as a guide.

2010s – Today

Runways for Growth

Snap-on is positioned for the future with favorable vehicle population trends, increasing vehicle complexity, growing demand in emerging markets and significant opportunities in industries outside of vehicle repair.

To capitalize on these opportunities, we are investing strategically in these wide runways for growth in order to reach more professionals.

Snap-on IndustrialCatalogue

THE NEW 900+ PAGE SNAP-ON CATALOGUE

Key product categories and features

- Tool Storage

- Hand Tools

- Power Tools

- Diagnostics

Our Programs

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe.

Make Foreign Object Damage a Thing of the Past

News &

Updates

Stay up to date with the latest news about our products and upcoming events.

Snap-on Industrial at Farnborough International Airshow 2024

Come and see Snap-on Industrial on stand at the Farnborough International Airshow 2024. We will be showcasing our Level 5 tool management system and torque products as well as various other tools…

Aviation engineers depend upon Snap-on’s Level 5 tool management system

Safran Landing Systems depend upon Snap-on Industrial’s Level 5 Automated Tool Management System which allows the use of any number of networked tool storage cabinets to be monitored from one control…

We’re helping to restore a Fokker F27

At Snap-on Industrial we’re proud to be supporting an ambitious project in the Netherlands to restore a vintage Fokker F27 and get it back in the air. Our knowledge and experience enabled us to…

Snap-on’s newly enhanced tool management system – launched at the prestigious Red Bull Racing headquarters in Milton Keynes

With Snap-on’s newly enhanced tool management system teams can now work even smarter and faster than ever before - launched at the prestigious Red Bull Racing headquarters in Milton Keynes.

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields