AutoCrib

AUTOCRIB INDUSTRIAL VENDING MACHINES.

Slash inventory expenses, increase worker productivity, and automate the procurement process.

The AutoCrib Advantage

Our industrial vending machines are built like tanks and provide point-of-use inventory management for industrial supplies. Workers log in or simply scan an ID card to issue or return items. The industrial vending system does the recordkeeping automatically just like a tool crib attendant, it can even re-order the products for you!

What makes industrial vending machines different?

- Purpose-built for industrial environments.

- Powerful inventory management software.

- No cash transactions. Employees log in with their existing employee badge.

- User interface designed for making complex inventory transactions easy.

- Flexibility to dispense a wide variety of item types and thousands of SKUs.

- Doesn’t require repackaging.

- You can return items back to the dispensing machine.

STANDARDIZE YOUR BUSINESS PROCESS

When you automate inventory management with an industrial vending machine you can replicate best practices across the entire company.

This is the most comprehensive way to implement lean inventory management efficiently and effectively.

With a standardized process and relevant inventory information you can: better bid on customer jobs, understand your real-world workflow, trace-back faulty lot controlled items for recalls and forecast inventory levels based on actual demand.

You always know which item they took, when they took it, what job it was used on and how many were taken. You know where your entire inventory is at any given moment with a complete inventory control system.

We help reduce consumption of up to 40%, reduce carrying cost, and provide accountability so that consumption never gets out of control.

Decentralized POU dispensing is more efficient than a single tool crib location, allowing for shorter waits, and better inventory tracking.

Our solutions can automatically build purchase orders and electronically send them to multiple suppliers at predetermined reorder points.

Our 24/7 support has a 98% solve rate. Our support portal includes live chat and a knowledge base of 1,000+ articles.

Our variety of models allows for scalability and customization. No matter what your needs are, we have a solution for you.

INTELLIPORT® LITE

The IntelliPort® Lite is a turnkey system of radio frequency identification readers (RFID) placed at a choke point to track the movement of RFID tags in and out of a controlled area.

The IntelliPort® Lite is a great choice for smaller storerooms and cribs. You’ll find the IntelliPort® Lite is the perfect solution for applications where a high number of items need to be issued or where there are many large or bulky items It’s excellent for high traffic cribs because multiple employees can “shop” simultaneously which eliminates long lines at the tool crib.

The IntelliPort® Lite delivers the lowest cost per vended item in high-volume environments. The IntelliPort® Lite can vend and track an unlimited number of items with all different types, sizes and shapes

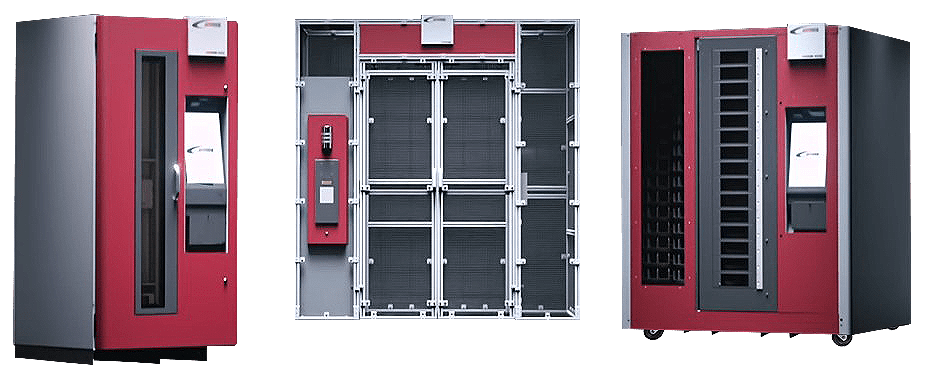

AUTOLOCKER® FX

AutoCrib has a smart locker system that is designed to be a modular storage and tracking solution.

Our rack mounted approach lets you build a custom configured locker system for the unique needs of your company and purchase only what you call for. No need to purchase excess lockers and use up valuable floor space.

See-through windows with bright LED lighting allow the user to quickly identify the items they want and then issue them through an intuitive touch-screen user interface. Multistate LED status lights communicate which items are out on the floor and the status of the items inside the lockers.

HOW CAN I CUSTOMISE MY SOLUTION?

You decide the frame size, locker size, optional features and weight capacity (AutoLocker FX Scale only). There are 16 different scaled modules and 22 standard doors and drawer sizes available for you to choose from. Modules come in a standard 24” (60cm) depth and a wide variety of heights and widths available that can be mixed and matched to provide a customized solution.

ROBOCRIB® TX750

Incredible Bin Density.

The system in its most dense (smallest) bin size configuration provides for up to 987 bins in roughly the same footprint as other competing vending machines.

Our patented plastic bin shelf system, mated with the incredibly flexible tambour style door, gives the machine the ability to virtually eliminate vertical bin “height” waste that is common with fixed door machines.

Dramatically Reduce Maintenance Costs

AutoCrib has vast experience has found that reducing the number of moving parts significantly reduces maintenance. Utilizing a dual tambour eliminates over 15 separate sub-systems and greatly reduces maintenance costs.

Dispense Square Packages or Boxes

The RoboCrib® TX750 is the first machine that was specifically designed to dispense square or rectangular boxes or packages. This practically eliminates the need for repackaging items to fit in helix coil machines or carousels that use pie-shaped bins. The dual tambour approach coupled with a machine that utilizes square bins allows for an incredible amount of flexibility in bin sizes from 2” (5cm) height to 60” (152cm) height.

Quickly Configure at the Customer Site

The simple user interface takes maximum advantage of the bin density and flexibility by simply sliding shelves into a rack. The machine walks you through a bin assignment process that is quick and easy. You can set up the machine with little to no prep work as you perform the initial stock or load.

Our Programs

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe.

Make Foreign Object Damage a Thing of the Past

News &

Updates

Stay up to date with the latest news about our products and upcoming events.

Snap-on Industrial at Farnborough International Airshow 2024

Come and see Snap-on Industrial on stand at the Farnborough International Airshow 2024. We will be showcasing our Level 5 tool management system and torque products as well as various other tools…

Snap-on support helps to transform automotive engineering at leading college

The Snap-on team take pride in working with the excellent Yeovil College to pursue a vital mission: developing the knowledge and skills of young people who will become tomorrow’s engineers and…

We’re helping to restore a Fokker F27

At Snap-on Industrial we’re proud to be supporting an ambitious project in the Netherlands to restore a vintage Fokker F27 and get it back in the air. Our knowledge and experience enabled us to…

Snap-on’s newly enhanced tool management system – launched at the prestigious Red Bull Racing headquarters in Milton Keynes

With Snap-on’s newly enhanced tool management system teams can now work even smarter and faster than ever before - launched at the prestigious Red Bull Racing headquarters in Milton Keynes.

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields