In December 2021, the distribution of new individual and mobile work cases started for all mechanics, non-commissioned officers and volunteers of the Land Component Mechanics (GT23V and GT53V), including the Logistics Training Center in Tournai. In other words, the cases are intended for all our Mec vehicles of the Land Component Mechanics.

The delivery of the 447 work cases is done by the contractor CEBEO. The company Katoen Natie in Beringen is responsible for the further distribution internally in Defense according to the distribution key of COMOPSLAND-G4. The 4 Bn Log is the first unit to receive a total of 77 cases. The cases are individualized and are also managed as a kit (5180-DE-021-1124). To facilitate management, an asset number was affixed to each case.

This file was realized under the leadership of the Equipment Manager MRSys-SUO and the purchasing department MRMP-S/AD.

1. The individualised cases are managed as a kit

2 – Delivery of the first work cases within the 4 Log Bn

Tools are an extension of our body

Hand tools have been around since prehistoric times. The transition from primitive Flintstone-era stone hand tools to advanced engineered tools is indispensable for the maintenance of our current and new weapon systems.

SAFETY

The importance of good hand tools should not be neglected and their condition is an important factor. Blunt tools such as scissors, cutters, saws, screwdriver tips – basically any tool in a bad condition – not only jeopardize safety, but also increase (sometimes by a factor of ten) the effort required to use them.

Presentation of the equipment

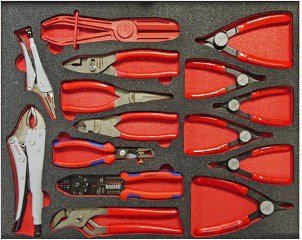

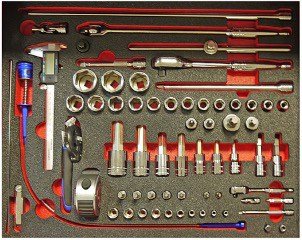

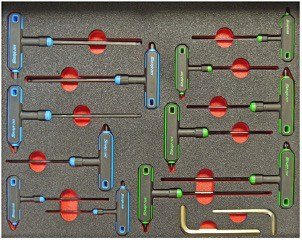

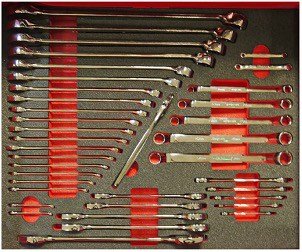

The work cases are composed of seven secure drawers and contain 242 hand tools including wrenches, adjustable wrenches, sockets, screwdrivers, pliers, hammers, air pump, multimeter, cutter, saw, …

Professional and quality equipment from the top brand SNAP ON as well as FACOM, KNIPEX, BAHCO, FLUKE was chosen. Quality not only guarantees a long service life, safety and ergonomics are also inherent characteristics. The work case can also be easily expanded with, for example, a top or side box. In addition, the new work cases come with a 10-year warranty.

Features of the actual case:

- Welded Locking Components

- Lock ‘N Roll® drawers for accidental opening during transport

- Ball guides for smooth operation

- Key lock for more security

- Fully double-walled construction with reinforcements between walls

- Threaded casters & handles on welded steel nut plates

- Drawer edge zooms provide strength and protection from sharp edges

Specification:

- Depth (mm) 508

- Width (mm) 660

- Number of drawers 7

- Height (mm) 940

- Net weight (kg) 77

- Loading capacity (kg) 499

- Sliding capacity (kg) 45

Incorrect selection of hand tools or faulty tooling can lead to:

- Injuries

- Varying quality of work,

- Reduced efficiency and productivity

- And self-damage to the equipment on which the maintenance is performed.

With the exception of the few tools that can be repaired, such as wood chisels or saws, worn tools must therefore be discarded and replaced with new equipment.

For the technicians / users, the delivery of the new tool is a motivating factor. The recruitment results have shown that technicians today are ‘hard to get’, i.e. it is imperative to keep them happy. Making their work more efficient and pleasant with new and adapted equipment increases their satisfaction and motivates them in the long term.

ORDER in disorder: ICS in the workplace

Lean management and ICS are important tools for smooth and structured work. These applications have been used in the automotive industry for years and have proven their worth. Where in the past the tools were casually deposited in a storage compartment, now each tool has its own location cut out in a contrasting (red-black) foam within the mobile work case. In this way, it is immediately apparent whether tooling is missing, which contributes to safety: tool control in the fight against FOD – Foreign Object Damage.

4 – assembly at the manufacturer

5 – ready to ship

Impressum DG MR Newsletter

Source – Mathieu Delbrassinne, Major

Layout – Johan Lievens, Major

Photos – Defence and Snap On

Head of Communication DGMR / Editing – Johan Lievens, Major

Responsible publisher – Directorate General Material Resources

Social Media – Facebook and Twitter

Contact – [email protected]

Neither the Ministry nor any other person acting on its behalf is responsible for any use that may be made of the information contained in this publication. All rights reserved. © DG MR 2022