ATI Airframe Tools

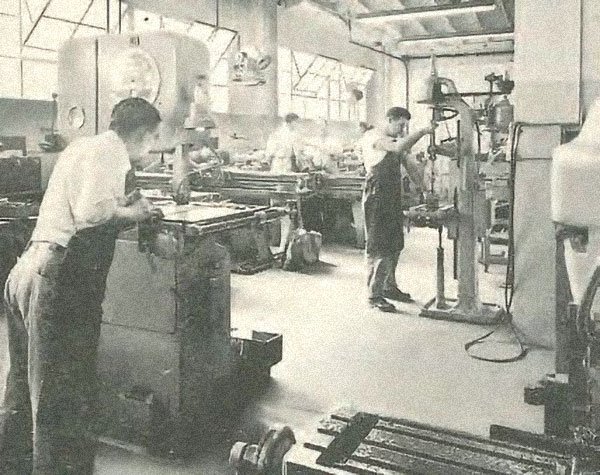

PRECISION AIRFRAME TOOLING SINCE 1938.

When you need the right answer on Airframe maintenance and repair tools, ATI Airframe Tools are unmatched in the market place.

A Seventy-Year Heritage of serving customers and airlines

With seventy years of experience in Airframe tooling, ATI Airframe Tools have every imaginable tool when it comes to Drilling, Countersinking, Riveting and Bucking procedures.

When you need the right answer on Airframe maintenance and repair tools, we’re unmatched in the market place. And if we don’t have the right answer in stock, we have a full service staff of experts who can create a custom tool solution made to your specific needs that will have you covered.

1938

ATI was formed in 1938 in Los Angeles, California and incorporated as Aircraft Tools, Inc., in 1949.

Strategically located near LA International Airport, we were able to serve Douglas, Northrop, Lockheed and North American Aviation.

1950

In the mid-1950s, we opened several U.S. sales offices in order to support other companies like Boeing, Grumman, Beech, Cessna, General Dynamics, LTV, Sikorsky, Rohr and Bell Helicopter.

As business changed in the late 1950s, we began soliciting machine shop work and formed a tool and an aerospace division that allowed us to grow substantially.

1960s – 1970s

In 1966, ATI relocated to Escondido, CA, just north of San Diego. It had established itself as the largest supplier of quality aircraft fabricating tools in the United States and Canada.

In 1972, the employees of ATI purchased the company and changed the name to ATI Industries. We began concentrating on international markets, setting up sales distribution into 35 countries.

1980s – 1990s

In March of 1986, ATI brand was sold to, and became a subsidiary of, Snap-on Tools Incorporated.

When defence budgets were drastically reduced in the early 1990s, ATI terminated all aerospace missile component work to concentrate solely on the core commercial tools business. In keeping with this focus, we changed our company name to ATI Tools, Inc. and kept that name until January 1, 1996, when we became ATI Tools Division, Snap-on Tools Company.

2000s – Today

In early 2009, ATI consolidated with CDI Torque, another Snap-on Tools company, and formed Snap-on Specialty Tools, which resides today in City of Industry, California.

Snap-on Specialty Tools has a full service design and engineering staff and the capabilities to build custom tools for specific applications.

Key Points

WIDE RANGING PRODUCT LINES

ATI Airframe Tools has precision quality products that are both specialized and commercial tools for airframe production, maintenance, and repair. The extensive product line spans riveting, bucking procedures, cable swaging, drilling, countersinking, aluminium cutting, specialized tools for airframe fasteners, and beyond.

ENGINEERING THAT EXCEEDS INDUSTRY STANDARDS

What sets ATI Airframe Tools apart? It begins with innovative design, precise heat treatment specification and rigid inspection standards add up to safe, functional, and cost-effective aircraft tools that don’t just meet aviation industry standards, they exceed them.

All ATI tools adhere to rigid engineering standards, including:

- ISO 9001, Quality Management

- ISO 14001, Environmental Management System

- 18001-199, Work Safety & Health Protection Management

- ISO 190011, Audit Management

- ISO 17025, Laboratory Calibration (ANSI NCSL-Z540-1)

- ANSI ASQ Z1 / MIL-STD-105E, Sample Inspection Plan

- and more…

Toolsfor Aviation and Aerospace

A Snap-on Specialty Tools Brand

The ATI Airframe Tools brand under Snap-on Specialty Tools will have a full service design and engineering staff and the capabilities to build a multilevel of variations of custom tools to your specific specifications.

Our Programs

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe.

Make Foreign Object Damage a Thing of the Past

News &

Updates

Stay up to date with the latest news about our products and upcoming events.

Snap-on Industrial Sponsoring Sanicole Airshow 2025

Snap-on Industrial is proud to announce its sponsorship of the prestigious Sanicole Airshow 2025, one of Europe’s premier aviation events.

Military aviation is on a mission – continually striving to improve its safety record, accountability, and compliance

Military aviation is on a mission, continually striving to improve its safety record, accountability, and compliance while simultaneously embracing the efficiencies provided by digitalisation…

We’re helping to restore a Fokker F27

At Snap-on Industrial we’re proud to be supporting an ambitious project in the Netherlands to restore a vintage Fokker F27 and get it back in the air. Our knowledge and experience enabled us to…

Snap-on Industrial unveils new product range inspired by customer feedback

Snap-on Industrial held its third annual Insight event at the Red Bull Technology Campus, an opportunity for the world-leading productivity solutions company to connect with its customers and preview…

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Snap-On.Committed to ensuring the safety of your staff and customers.

Workmanship, quality and innovation have a long tradition at Snap-on. Our products are light, durable, strong and, above all, safe. If you'd like to know more about our range of products download our catalogue below.

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields

Can we help?

Please fill in your details below and a member of our dedicated team will be in touch.

"*" indicates required fields